Quality

Chesapeake CNC has a Dedicated Quality Control Department to better serve our customers.

All parts are inspected based on customer ranking and through an AQL (Acceptable Quality Level) sampling plan. A monitored in-process check system that complies with ISO standards is implemented and continuously improving.

We have a first article inspection (FAI) process to ensure that first production parts meet customer requirements and/or standards.

Along with standard inspection equipment, we have the following modern inspection equipment to ensure proper in-process quality control.

We have the following modern inspection equipment in our facility to insure proper

in-process quality control:

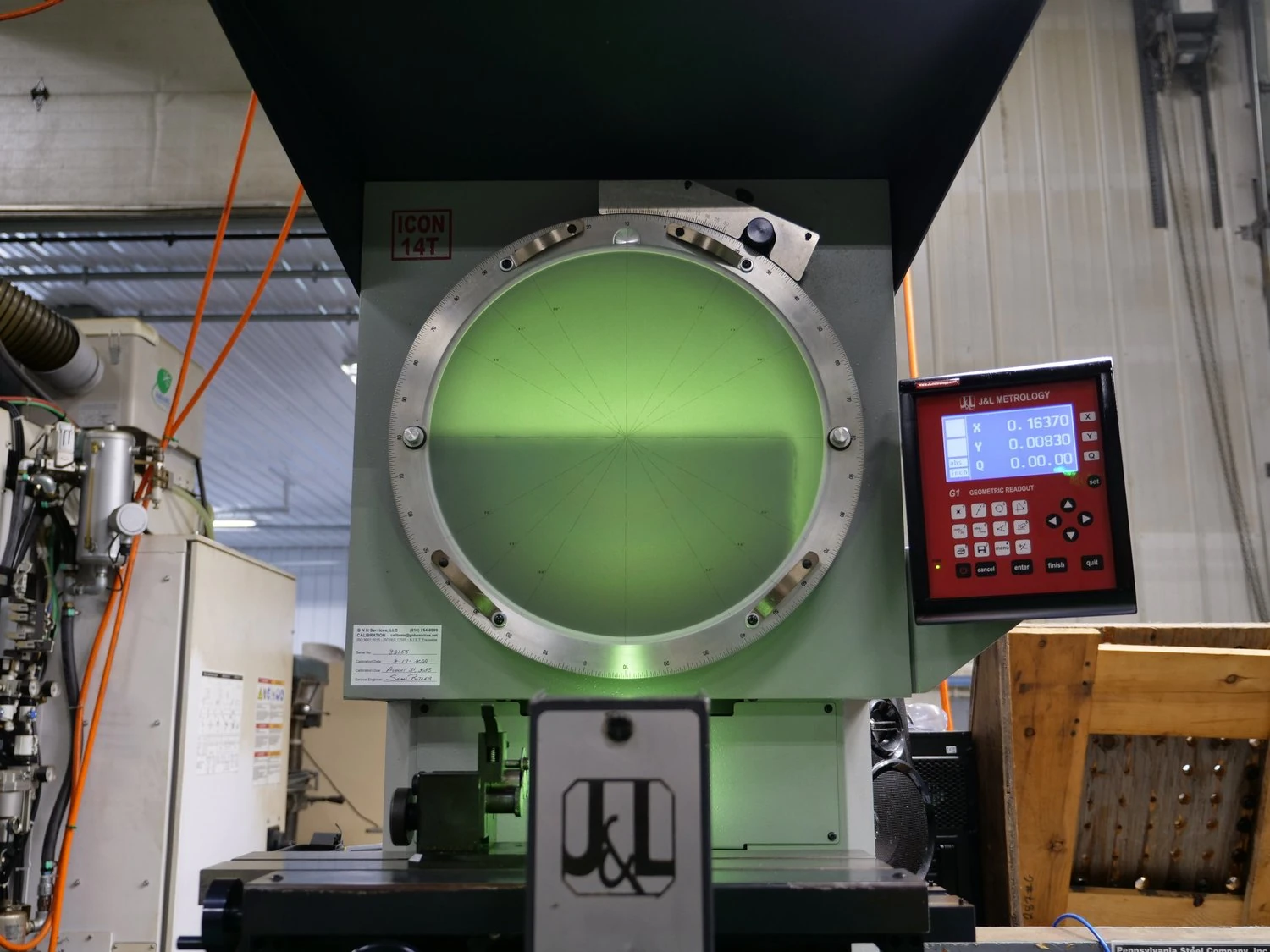

- QV1 STARLITE RAM OPTICAL COMPARATOR

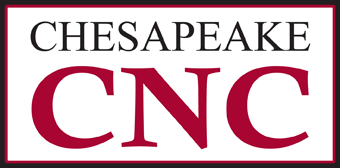

- MITUTOYO SURFACE MICROMETER

- DELTRONIC DH 216 OPTICAL COMPARATOR

- CERTIFIED PINS AND GAUGES

- MITUTOYO MEASURLINK QUALITY MANAGEMENT SOFTWARE